detalye ng Produkto

Detalyadong Paglalarawan ng Produkto

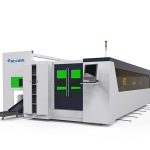

| Lugar ng Pagputol: | 1500 * 3000mm | Paglamig na Mode: | Pagpapalamig ng tubig |

|---|---|---|---|

| Power ng Laser: | 1000W | Mag-load ng Maximento ng Loob: | 1000kgs |

| Pag-posisyon ng Katumpakan: | ± 0.05 Mm | Transport Package: | Seaworthy Plywood Case |

| Technical Class: | Patuloy na Wave Laser | Application: | Agriculture Machinery, Automotive Industry, Advertising Industry, Metal Processing |

Paglalarawan ng Produkto

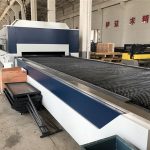

1.The strong frame is completely welded, high temperature annealing and stress relief treatment to ensure no deforming.

2. Imported high precision ball screw transmission / rack & pinion, high precision linear guide rail.

3. Imported servo motor and drive, imported high-rigidity precision gearbox.

Equipped with auto-lubrication device, with dust removal and smoke extract system in cutting area.

4.Modular structure of laser generator, high performance and free from maintenance

Professional laser cutting software, easy, convenient and smart to operate, easily design all kinds of graphics and texts for cutting.

Advantages over Other Cutting Machines

1. The super high photo-electric conversion efficiency can be up to about 30%. So the machine runs with the lowest power consumption compared to other laser cutting machines under the same output power. So the cutting cost is the lowest.

2. With laser beam of good quality from double-clad fiber(DCF), the focus spot is superfine, and the cutting seam is very even and fine. Then the efficiency can be higher, and the quality is better.

3. The surface-area-to-volume ratio (SVR) of the gain medium is big.

4. The light path is totally composed of fiber laser and fiber laser units, which are combined together based on cable splicing technology. And the whole light path is enclosed in fiber laser waveguide.

5. No laser working gas and can start cutting just by blowing air. And fiber optic transmission requires no need of reflector mirrors. In a word, the machine saves maintenance costs greatly.

6. The efficiency is very stable and reliable by adopting the diode pump laser module. No need to adjust the light path. So it’s easy to operate and maintain the machine.

7. Key units have the working life of 100 thousand hours.

8. High output power from 200 to 4000w can be customized.

9. The machine costs little water and energy. And the machine requires no gas. So the running cost is lower.

What Materials Can our Machine Cut ?

| Materyal | Pagputol ng kapal (mm) | Pagputol bilis (m / min) | Pagputol ng gas | Ang pagputol ng presyon | Nozzle | Collimator / Pokus |

| Carbon steel | 0.5 | 30-40 | Air | 6 | 1.5 solong layer | 75/125 |

| 0.8 | 20-25 | Air | 8 | 1.5 solong layer | 75/125 | |

| 1 | 18-22 | Air | 10 | 2.0 solong layer | 75/125 | |

| 2 | 5-6.5 | Oxygen | 3.5 | 1.2 dobleng layer | 75/125 | |

| 3 | 3-3.5 | Oxygen | 0.5-1 | 1.2 dobleng layer | 75/125 | |

| 4 | 2-2.3 | Oxygen | 0.5 | 1.2 dobleng layer | 75/125 | |

| 5 | 1.5-1.8 | Oxygen | 0.5 | 1.2 dobleng layer | 75/125 | |

| 6 | 1.2-1.4 | Oxygen | 0.5 | 1.5 dobleng layer | 75/125 | |

| 8 | 0.9-1.2 | Oxygen | 0.5 | 2.0 dobleng layer | 75/125 | |

| 10 | 0.7-0.8 | Oxygen | 0.5 | 2.5 dobleng layer | 75/125 | |

| 12 | 0.5-0.65 | Oxygen | 0.5 | 2.5 dobleng layer | 75/125 | |

| Hindi kinakalawang na Bakal | 0.5 | 30-40 | Nitrogen | 7 | 1.5 solong layer | 75/125 |

| 0.8 | 22-25 | Nitrogen | 10 | 1.5 solong layer | 75/125 | |

| 1 | 20-23 | Nitrogen | 12 | 1.5 solong layer | 75/125 | |

| 2 | 6-7 | Nitrogen | 15 | 2.0 solong layer | 75/125 | |

| 3 | 2.5-2.8 | Nitrogen | 18 | 2.0 solong layer | 75/125 | |

| 4 | 0.8-1.2 | Nitrogen | 18 | 2.0 solong layer | 75/125 | |

| 5 | 0.6-0.8 | Nitrogen | 18 | 2.0 solong layer | 75/125 | |

| Aluminyo | 0.5 | 20-25 | Air / Nitrogen | 8 | 1.5 solong layer | 75/125 |

| 0.8 | 15-18 | Air / Nitrogen | 9 | 1.5 solong layer | 75/125 | |

| 1 | 10-12 | Air / Nitrogen | 12 | 1.5 solong layer | 75/125 | |

| 2 | 3-3.5 | Air / Nitrogen | 18 | 2.0 solong layer | 75/125 | |

| 3 | 1-1.5 | Air / Nitrogen | 18 | 2.0 solong layer | 75/125 | |

| Tanso | 0.5 | 22-30 | Nitrogen | 12 | 1.5 solong layer | 75/125 |

| 0.8 | 13-17 | Nitrogen | 12 | 1.5 solong layer | 75/125 | |

| 1 | 10-12 | Nitrogen | 15 | 1.5 solong layer | 75/125 | |

| 2 | 2-3 | Nitrogen | 18 | 2.0 solong layer | 75/125 | |

| 3 | 1-1.3 | Nitrogen | 18 | 2.0 solong layer | 75/125 | |

| Copper | 0.5 | 15-18 | Oxygen | 12 | 1.5 solong layer | 75/125 |

| 0.8 | 8-12 | Oxygen | 12 | 1.5 solong layer | 75/125 | |

| 1 | 5-7 | Oxygen | 12 | 1.5 solong layer | 75/125 | |

| 2 | 0.8-1.2 | Oxygen | 15 | 2.0 solong layer | 75/125 |

Applied materials of 1000W Fiber Laser Cutting Machine

Ang hibla ng pamutol ay pangunahing ginagamit para sa pagputol ng bakal ng carbon, banayad na asero, hindi kinakalawang na asero, silikon na bakal, aluminyo haluang metal, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, tanso at maraming uri ng mga materyales na metal. Ito ay isang cutter ng cnc laser ay maaaring magamit upang gawin ang mataas na paggupit ng katumpakan. Maaari rin itong tawaging fiber cutter machine, fiber optic laser cutter, laser cutter para sa metal, fiber cutter, carbon steel cutting, cnc laser cutter.

Teknikal na Parameter

| Working Area | 3000 * 1500mm |

| Controller + Heigh tagasunod | Cypcut |

| Pinagmulan ng Laser | Fiber Laser Source 1000W |

| Haba ng Wave | 1070nm ± 10nm |

| Laser Head | Opsyonal |

| Gear at Rack | Alemanya |

| Patnubay sa Rail | Taiwanese HIWIN |

| Posisyoning Katumpakan | ≤ ± 0.04mm |

| Pagputol ng Pagkapal | 1-12mm |

| Ang bilis ng pagputol ng Max | 40000mm / min (ayon sa mga materyales) |

| Paggawa boltahe | AC220V / 110V ± 10% 50HZ / 60HZ |

| Lapad ng linya | ≤0.12mm |

| Paghahatid | Yaskawa servo 850W + FASTON reducer |

| Z axis | Yaskawa 400W + preno |

| Palamig | Pagpapalamig ng tubig |

| Istraktura | 10mm Thickness Welded steel tube, Aluminum Alloy Gantry |

| Konsumo sa enerhiya | ≤7.5KW |

Applied Industry of 1000W Fiber Laser Cutting Machine

Ang laser cutter na ito para sa metal ay inilalapat sa sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway bahagi, sasakyan, makinarya, katumpakan na sangkap, barko, metalurhiko kagamitan, elevator, gamit sa sambahayan, regalo at crafts, pagproseso ng tool, adornment, advertising, metal dayuhang pagproseso ng iba't ibang mga industriya sa pagpoproseso ng pagmamanupaktura.